This then becomes an operation for one of our cnc press brakes.

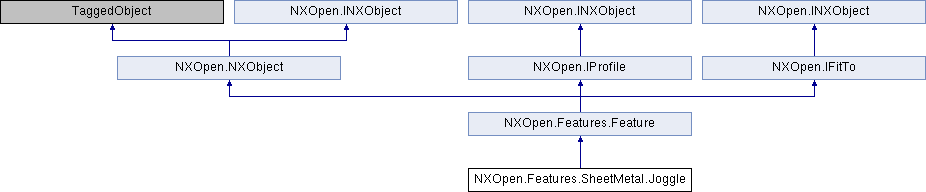

Sheet metal joggle dimensions.

Next month concludes with the pros and cons of hems jogs and forming tools.

Columnist gerald davis continues a discussion of 3 d cad and precision sheet metal manufacturing in part iii of a four part series focusing on design guidelines for sheet metal.

Previous editions covered economic order quantity in batch production and the accuracy of things made from rolled sheet stock.

Once dimension x increases in the joggled formed in the sheet metal above the maximum shown in the table we have to put the 2 bends into the sheet separately.

The inside joggle radii should be approximately the same as used for straight bending.

A joggle bend in sheet metal and a joggling tool joggling 5 also known as joggle bending is an offset bending process in which the two opposite bends are each less than 90 see following section for how bend angle is measured and are separated by a neutral web so that the offset in the usual case where the opposite bends are equal in.

Have your folks make an exemplar of the die s product using the correct material measure it and make a standard detail drawing of the exemplar and a superimposed layer or sheet showing how the finished features relate to the dimensions of the actual die.

A joggle is an offset formed to provide for an overlap of a sheet or angle which is projecting in the same plane.

Folding sheet metal components using our trumpf 7036 cnc press brakes and special joggle tooling ever wondered how we produce a double bend often called a joggle.

You only have to insert interior angle flange lengths k factor inside radius and material thickness.

For sheet metal work over 140mm long please see our cnc z bend table.

Well this type of z shape can be produced by simply bending using a v bend block and then turning the component over and bending again to achieve.